Top-level anti-corrosion protection: premium protection for the new reception hall at Frankfurt Airport

If you travel frequently, you have probably landed at Frankfurt Airport at least once, as have millions of passengers every year. The new Terminal 3 for passengers includes an impressive check-in hall. The Austrian company Haslinger Stahlbau GmbH, a long-standing partner of KANSAI HELIOS Group, is responsible for the construction and design for the hall. The entire steel structure is protected with an advanced anti-corrosion coating system.

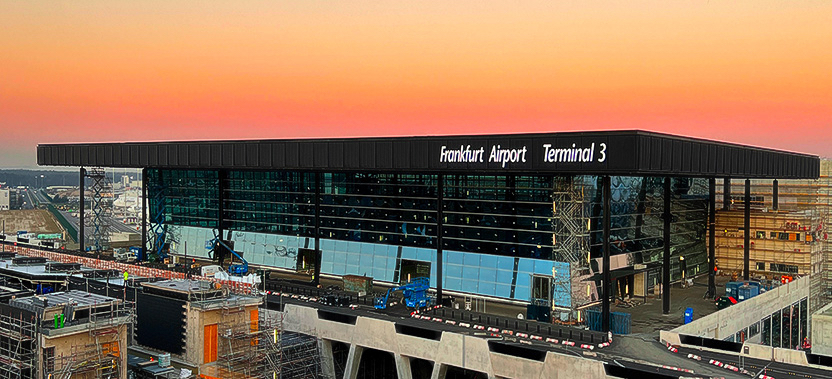

KANSAI HELIOS provides premium anti-corrosion protection and meets the highest standards for the steel structure of the check-in area of the new Terminal 3 at Frankfurt Airport. We present an exclusive behind-the-scenes look at one of Europe’s largest infrastructure projects.

Modern, robust and well protected

One of Europe’s largest infrastructure projects is currently taking place in Frankfurt, covering an area of 176,000 square metres. The new Terminal 3 with a modern check-in hall is being built in the southern part of the airport. This impressive space will serve as the entry point for departing passengers and will accommodate up to 19 million passengers annually.

The Austrian steel construction company, Haslinger Stahlbau GmbH, is building the steel structure of the hall and aircraft docking bays, relying on KANSAI HELIOS anti-corrosion coatings as a long-standing partner. The 18-metre tall hall is surrounded with an almost continuous steel-glass facade of impressive dimensions: 150 metres long and 78 metres wide. The roof structure has a total length of 200 metres and extends over 20 metres beyond the edge of the hall on all sides. The roof is supported by 30 slender cantilevered columns and is laterally restrained at only two fixed points.

Anti-corrosion protection for the highest standards

The entire steel structure of the new terminal at Frankfurt Airport is protected by a comprehensive anti-corrosion system consisting of a primer, an intermediate coat and a top coat. The coating system is specially designed for corrosion category C4 – high. The final colour shade, RAL 9005 in a matt finish, was especially challenging. Applying matt shades is challenging as the transitions between the start and end of rolling can remain visible. To avoid this, the KANSAI HELIOS Group has developed a special coating system that ensures a uniform and aesthetically pleasing appearance. This modern system reduces maintenance costs from the start and ensures the safety and functionality of the infrastructure for decades – rust does not stand a chance.

PROTECTIVE COATING SYSTEMS IN SHORT

GENERAL CONSTRUCTION – factory application (total DFT: 240 µm)

- Base coat: Remoplast Speed Dry (2K-EP/ZP) red-brown NDFT: 70–90 μm

- Intermediate coating Remoplast HS PUR Primer (2K-PUR) RAL 7016 NDFT: ~110 µm

- Finishing coat: Remoplast UVC PL ES MATT RAL 9005 MATT NDFT: 50–60 μm

CROSS BEAMS, FACADE

- First two layers at the factory:

- Base coat: Remoplast Speed Dry (2K-EP/ZP) red-brown NDFT: 70–90 μm

- Intermediate coating Remoplast HS PUR Primer (2K-PUR) RAL 9011 NDFT: 120–140 μm

- Final coat on site:

- Remoplast UVC PL ES MATT RAL 9005 MATT NDFT: 30–40 μm

Highlights of the construction process

“The absolute highlight of the project implementation was the installation of the approximately 8,000-ton roof structure,” emphasises Arno Sorger, Managing Director of Haslinger Stahlbau GmbH. “Due to construction logistics, there was only one solution for assembling the roof structure: to assemble the roof on a special assembly platform and then move it to its final location on specially designed sliding rails.”

The impressive roof structure which covers 26,000 m², was divided into five segments, each weighing approximately 1,600 tons. As Sorger describes, these segments were assembled on a specialised assembly platform, at a height of 28 metres. Then they were gradually moved to their final position along five sliding rails, a total of 200 metres, using hydraulics. The assembly platform itself, called MOHIKO, was a steel structure with an area of 6,500 m² and an impressive weight of 2,000 tons.

Approximately 12,500 tons of steel coated with around 200 tons of protective coating were used for the new reception hall at Frankfurt Airport. Photo: © Haslinger Stahlbau GmbH

The construction of the hall requires the effective coordination of technology, logistics and scheduling.

Photo: © Haslinger Stahlbau GmbH

The reception hall of the new Terminal 3 is a representative entrance space for departing passengers.

Photo: © Haslinger Stahlbau GmbH