Epoxy and polyurethane resin flooring: the pros and cons

Floors based on synthetic resin, also called industrial floors, have a long history of application, particularly in industrial and public facilities.

Recently, however, they have been increasingly installed in private premises, mostly as an alternative to ceramic tiling and to achieve a modern, minimalist finish without any grout joints and gaps. Epoxy (EP) and polyurethane (PU) floors are the two most common types of industrial flooring in standard use.

Flooring systems based on epoxy resins (EP)

Epoxy floors are used exclusively in interiors: industrial facilities, warehouses, garages, workshops and similar facilities where the floors must sustain heavy moving vehicles, the use of forklifts and freight trolleys and greater exposure to wear in general. Typical epoxy floors are very hard, resistant to wear and pressure. Because they are hard, they may not be used to bridge cracks, and before installation the substrate needs to be prepared with care. EP floors are resistant to water and the effects of many common chemicals used in industry, and their surface is smooth, hard and easy to maintain. Due to their high aesthetic value and endless possibilities for decorative design, EP floors are used in public spaces such as salons, stores, restaurants etc. and in the decoration of residential spaces. The technology of epoxide resins allows the application of flooring with 100% volume epoxy resins such as the Floor Expert primers EP 101 and EP 1013 and colour topcoats of self-levelling floors: Floor Expert EP 211 and Floor Expert EP 311. Composite systems, where quarts sand is sprinkled on the middle layer and/or added to epoxy self-levelling layers, are used to achieve greater thickness, anti-slip surface properties and resistance to wear.

Floor Expert EP 310W, a thin-layer water-based epoxy topcoat, can be diluted with water and applied with a machine or a roller. A typical application is the renewal of floors in private garages or the renewal of floor and wall tiling in sanitary facilities, kitchens or similar areas, where the entire surface of the tiled surface is painted to cover the groats and enable sanitary use of the room.

Flooring systems based on polyurethane resins (PU)

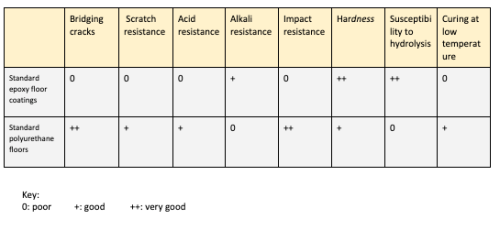

In comparison with EP floors, polyurethane floors are more flexible and therefore more resistant to surface scratching. As regards exposure to chemicals, PU floors are better suited to applications in food industries which produce dairy products and beverages because of their greater resistance to organic acids. Since their softer surface muffles the sound of steps to some extent, PU floors are also a good option for flooring residential and public spaces. Polyurethane floors are more sensitive to moisture during application than epoxy coatings, which makes their installation somewhat more challenging. Typical PU coatings are sensitive to hydrolysis and therefore may not be applied directly to concrete substrates. This is the reason why in PU flooring systems, the primer must be an epoxy coating such as Floor Expert EP 101 or EP 1013. Floor Expert PU 211 HE is a tough-elastic self-levelling floor containing no solvents (100% solid matter volume), which is used as a topcoat in interiors only. It is water-resistant, with the perfect ratio between surface hardness and elasticity. Its finish is smooth and glossy and can also be used as the bearing layer in anti-slip flooring systems. By applying Floor Expert PU 300W (matte or semi-gloss), a PU transparent water-based lacquer, you can give the surface a matte or semi-glossy finish and additional protection. Floor Expert 310 is a thin-layer, tough-elastic acrylic polyurethane topcoat based on solvents. It is used as a topcoat on exterior and interior concrete floor surfaces such as patios, warehouses, production areas, garages etc. It is also used as a topcoat in systems that include Floor Expert PU 211 HE.

Regardless of the choice of system, the most important step of installation is to prepare the substrate properly (by shot blasting or grinding) and ensure suitable conditions for installation – air and surface temperature and air and substrate humidity. Also, the area must not be draughty.

Properties of epoxy and polyurethane floor coatings